What Is Extended Producer Responsibility?

Extended Producer Responsibility, or EPR for short, increased in popularity in 2021, with sustainability and the environment at the forefront of consumer and business conversations. A growing movement believes that companies should be accountable for their products through product stewardship, a concept also known as Extended Producer Responsibility.

EPR can significantly impact how businesses and waste management operations work in the decades to come through corporate governance, regulation, and consumer influence. But it’s not a magic pill, and knowing the pros and cons of the concept is critical to making informed sustainable decisions.

What Is Extended Producer Responsibility?

Extended Producer Responsibility is a strategy that shifts responsibility for waste disposal and recycling after consumers from municipalities, trading companies, and other end-users back to the producers. The concept, first introduced by the Swedish professor Thomas Lindquist, aims to prevent waste at the source, promote sustainability, develop high-performance products, and minimize the adverse effects of improper waste disposal on human health and the environment. When the concept of E-waste management was introduced in India, the policy and laws came into effect in 2011, Lakshmi Raghupati being one of the significant contributors to this revolution.

Traditionally, end users dispose of waste by hiring the services of a disposal company to collect, transport, and dispose of the materials, that are sent to landfill for various reasons. Transferring this responsibility to producers can reduce waste, create a more efficient and “circular” supply chain, and encourage more sustainable products, which in some cases are more profitable to producers.

However, Extended Producer Responsibility is not just a guideline. Ultimately, EPR comes in a wide variety, with producers utilizing the following mechanisms:

Fiscal: Producers pay taxes, levies, or financial investments in programs that offset the environmental impact on the environment. It is often a regulatory measure taken by the state governments, but it can also be voluntary.

Product Design: Redesigning a product, from composition to packaging. Like using less raw materials or packaging or using a higher percentage of recycled materials during producer.

Supply Chain and Collection: Producers encourage their suppliers to reduce the environmental footprint, collect waste, and facilitate your product circulation in all phases of the life cycle. Email callback, in-store pickup, and buyback programs are common examples.

From The Start… To The End

As already mentioned, attitudes towards more sustainability and environmental protection are at an all-time high. However, consumerism and the “throwaway culture” are inconsistent with these conflicting initiatives. It’s a never-ending circle that repeats itself every time, albeit with new materials.

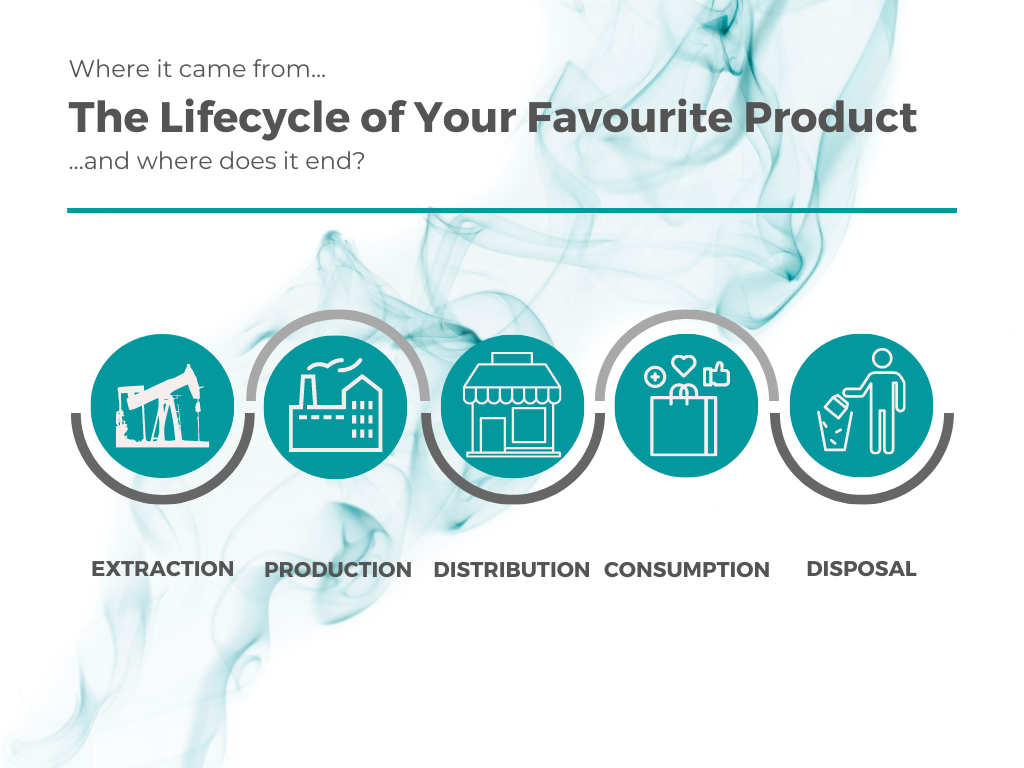

Natural resources are extracted from the earth to create new products, made into products, sold to consumers, and used as waste until disposal (which explains how people worldwide produce more than two billion tons of municipal waste annually). Extraction is a significant concern for both environmentalists and economists.

Through a more circular supply chain or product redesign, EPR can overcome strong dependencies on natural resources. For those who support Extended Producer Responsibility, it’s all about operational sustainability.

Expanded by the COVID19 pandemic, the cost and availability of raw materials have created nightmares for supply chains worldwide. Aside from wood, computer chips, and pool chlorine, producers have faced massive shortages of aluminum, glass, and even old corrugated cardboard – materials known for being recyclable and processable.

Here are a few facts to further outline why extended producer responsibility is something that companies need to invest in:

• Making new aluminum products from recycled aluminum saves more than 90% and even up to 95% of the energy required to make new metal.

• Using one kilogram of recycled waste glass can replace 1.2 kilograms of raw materials, and the production of glass from waste glass uses 30% less energy.

• Even plastics from consumables show significant reductions in energy consumption and greenhouse effect production in the reprocessing process.

Improving design has also proven to be an environmentally friendly measure for producers as they can change the structure and footprint of their recycled products. The voluntary EPR also has social implications as the scarcity of raw materials, and ubiquitous plastic pollution has reinvigorated the reputation for protecting our environment.

GreenTek Reman is one of the leading IT Asset Disposition & e-waste Management companies in India. With a decade worth of experience in the Reuse, Recycling, and Recovery of precious resources from electronic waste, the company offers a gamut of Extended Producer Responsibility (EPR) services from helping the paperwork to e-waste collection and recycling electronic waste for our clients.